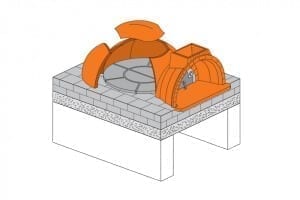

Modular ovens – Installation guide

The installation plays a key role in the success of a traditional wood-burning oven. Alfa wants to simplify the assembling process by realizing prefab modules that combine in blocks. Few individual pieces that compose a great oven whose resistance is increased by an internal reinforcement that make the dome rock-solid. Undoubtedly, choosing the appropriate materials for insulating the professional oven is crucial.

The Refrax grey mortar is the best ally to give the oven the right elasticity to “breathe” and to allow the appropriate thermal expansion of all the elements. Last but not least, the easy-to-apply ceramic fibre guarantees an optimal thermal insulation of the oven. All that means that you will make less effort and save time in the installation and drying process of a product that will lasts for a lifetime.

Step 1

Create two supports in masonry about 75 cm high to get a fire floor about 110 cm high. Place a concrete load-bearing slab about 15 cm thick.

Step 2

Create a floor about 15 cm high with panels made of light cellular concrete or concrete lightened with expanded clay or vermiculite.

Step 3

Place the sill of the exhaust fume and then the arch.

Step 4

After wetting the floor, spread a thin layer of Refrax (page 106) with a toothed spatula to lay down the pieces composing the floor.

Step 5

Wet the interstices between the pieces that make up the fire floor and fill them with Refrax, taking care to keep the filling slightly lower than the floor, to avoid impacts from the oven peel. The space between the floor and the walls of the dome should be left undisturbed and should not be plastered.

Step 6

After mounting the dome make sure the pieces are fully settled.

Step 7

After wetting the joints between the various pieces that make up the dome, spread 5 cm of Refrax on the outside. If you want to have greater thermal inertia, it is recommended to cast a layer of Refrax all over the dome of a thickness of up to 6 cm. In larger ovens, a thin wire mesh must be added to Refrax.

Step 8

After the layer of Refrax, thermally insulate the oven by placing multiple layers of ceramic fibre on the dome. We recommend an initial 2/4 cm layer of ceramic fiber followed by a 10/15 cm layer of vermiculite, expanded clay or rock wool for high temperatures.

Step 9

If you want to maintain the spherical shape of the open-view oven, you can make a 3/4 cm casting of sand and cement to place above the outer insulation, on which a layer of metal mesh has been positioned previously.

Step 10 A

If the oven is installed outside, it must be protected from rain and moisture.

Step 10 B

N.B: the oven in the design has been installed with the dome in sight (A) but the finishing touches vary according to the customers liking (mosaic, brick, etc). It is recommended to always use fireproof materials, also in the case (B) of built-in installation.

How much ceramic fiber and mortar to use?

| INTERNAL DIAMETER | CERAMIC FIBER | MORTAR |

|---|---|---|

| 80 cm | 2 rolls | Kg 75 |

| 90 cm | 2,5 rolls | Kg 85 |

| 100 cm | 3 rolls | Kg 100 |

| 110 cm | 4 rolls | Kg 135 |

| 120 cm | 4,5 rolls | Kg 150 |

| 130 cm | 5 rolls | Kg 170 |

| 140 cm | 6 rolls | Kg 200 |

| 160 cm | 6,5 rolls | Kg 230 |

| 180 cm | 9 rolls | Kg 320 |